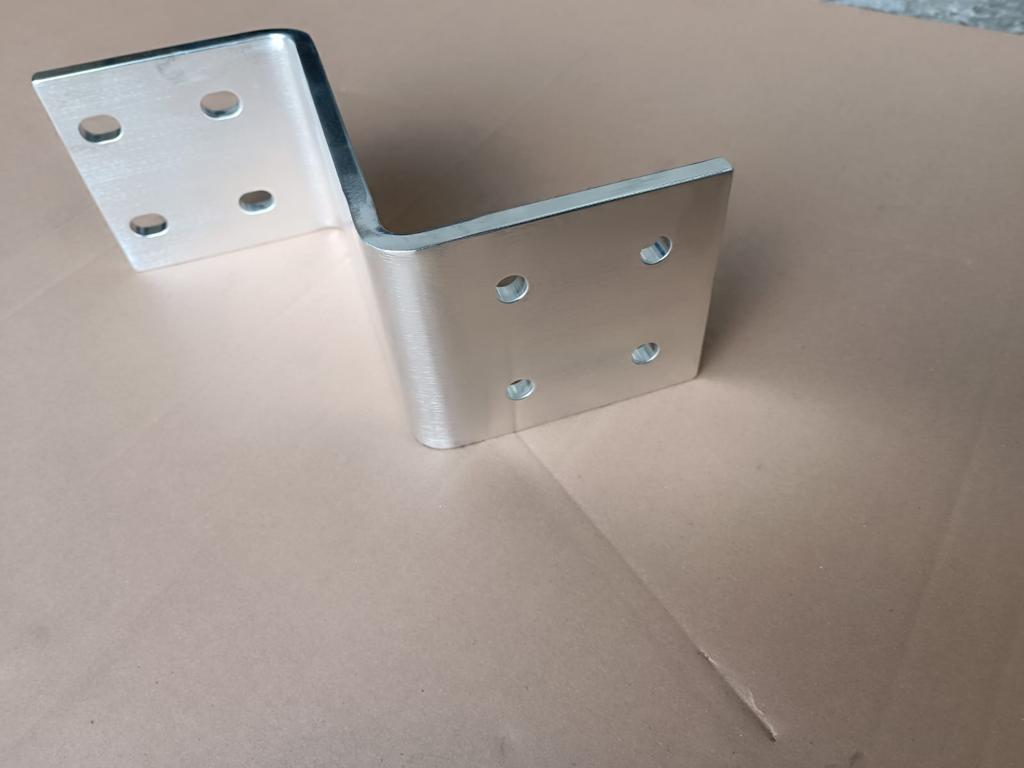

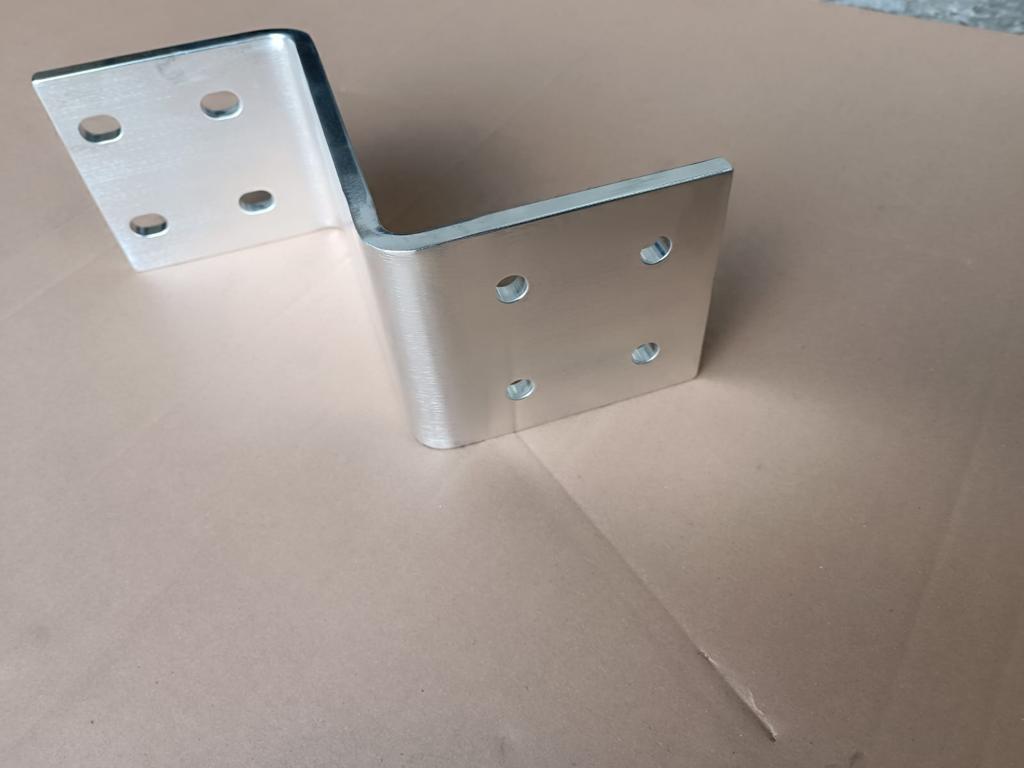

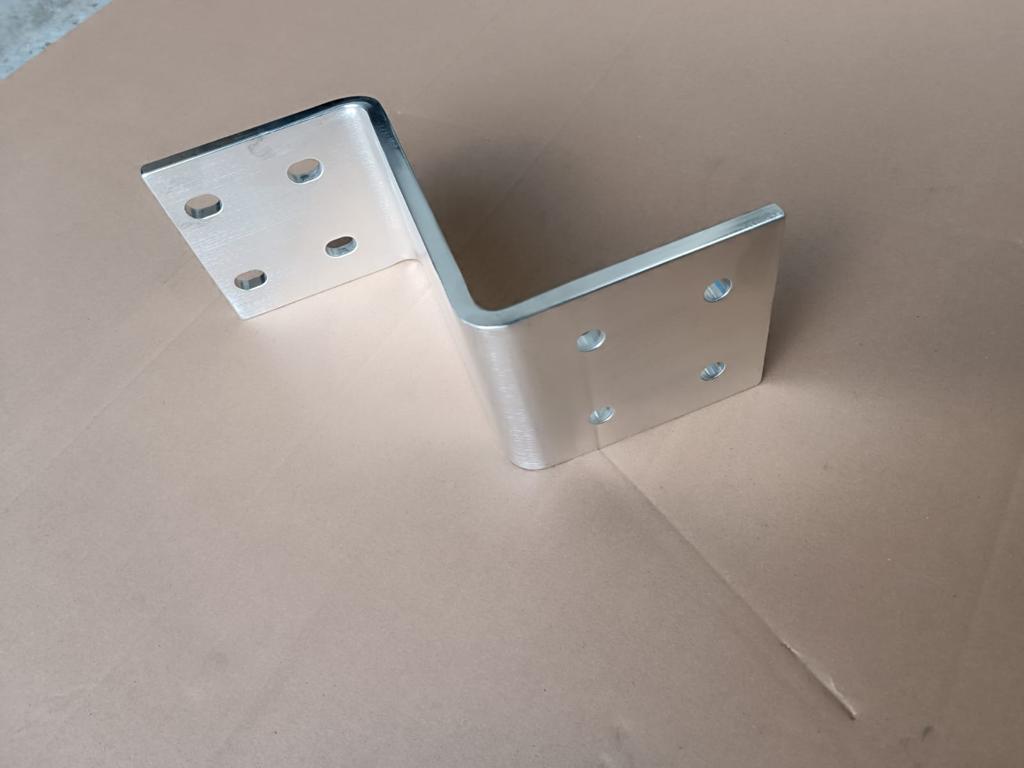

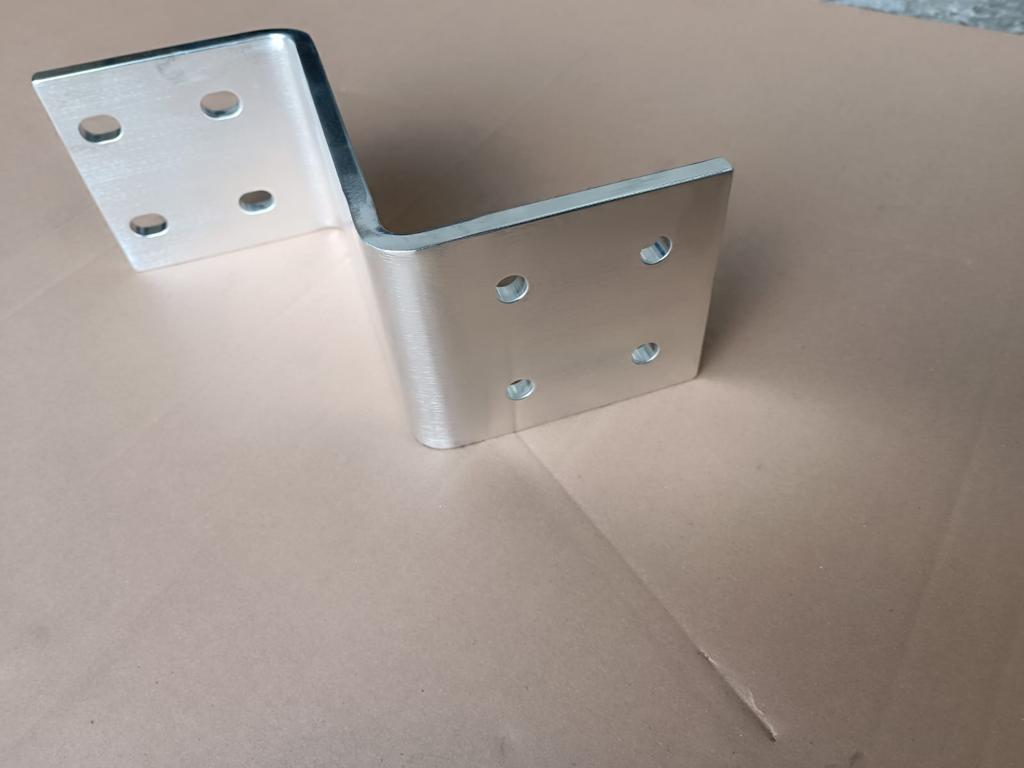

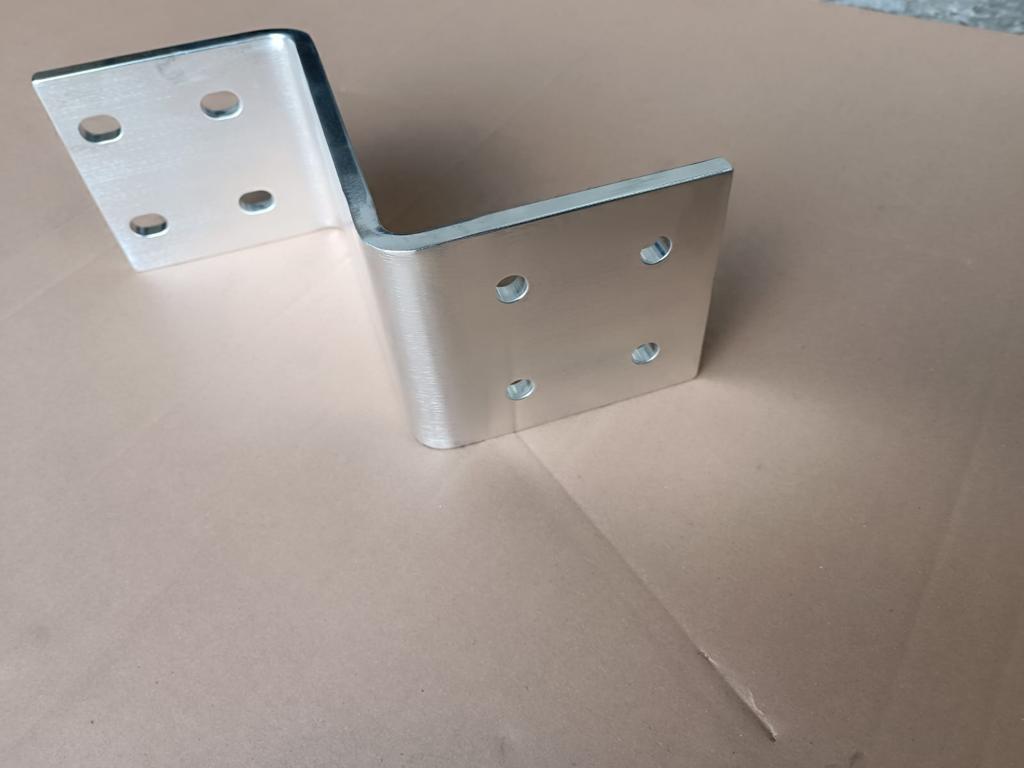

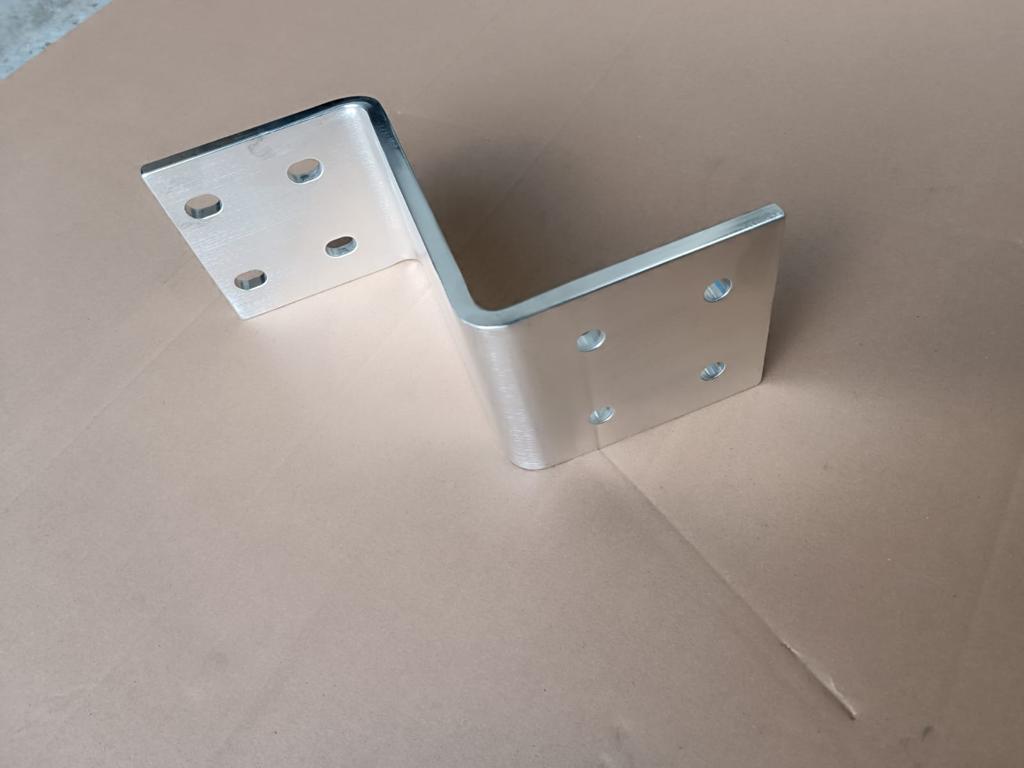

Tin Plating

Tin Plating

Tin plating is the process of applying tin to the surface of metal objects. This process is usually carried out by the electroplating method. The metal object is placed in an electrolytic solution and the tin ions are attracted to the surface of the metal object by the applied electric current. Thus, a thin layer of tin is formed on the surface of the metal object.

Tin Plating

Tin plating is the process of applying tin to the surface of metal objects. This process is usually carried out by the electroplating method. The metal object is placed in an electrolytic solution and the tin ions are attracted to the surface of the metal object by the applied electric current. Thus, a thin layer of tin is formed on the surface of the metal object.

Technical Specifications

- Electrical Conductivity: Tin plating is highly conductive in the electrical industry, ensuring efficient operation of electronic components and cables.

- Corrosion Resistance: With high corrosion resistance, it provides long-lasting protection in equipment used in the marine and aerospace sectors.

- Appearance Options: Available in bright or matte finishes, making it suitable for aesthetic and decorative applications.

- Thickness Control: It can be applied in desired thicknesses, allowing it to meet various industry needs.

Applications

Energy Sector:

- Electrical transmission lines

- Power transformers

- Renewable energy systems

Electronics and Electrical Industry:

- Electronic circuit boards

- Cable connections

- Semiconductor components

Marine Industry:

- Hulls of marine vessels

- Underwater equipment

- Marine electronic systems

Aerospace Industry:

- Aircraft bodies

- Electronic modules for aircraft

- Flight control systems

Food Industry:

- Food packaging machines

- Hygienic production equipment

- Food storage containers

For custom size production requests, please contact us.

Technical Specifications

- Electrical Conductivity: Tin plating is highly conductive in the electrical industry, ensuring efficient operation of electronic components and cables.

- Corrosion Resistance: With high corrosion resistance, it provides long-lasting protection in equipment used in the marine and aerospace sectors.

- Appearance Options: Available in bright or matte finishes, making it suitable for aesthetic and decorative applications.

- Thickness Control: It can be applied in desired thicknesses, allowing it to meet various industry needs.

Applications

Energy Sector:

- Electrical transmission lines

- Power transformers

- Renewable energy systems

Electronics and Electrical Industry:

- Electronic circuit boards

- Cable connections

- Semiconductor components

Marine Industry:

- Hulls of marine vessels

- Underwater equipment

- Marine electronic systems

Aerospace Industry:

- Aircraft bodies

- Electronic modules for aircraft

- Flight control systems

Food Industry:

- Food packaging machines

- Hygienic production equipment

- Food storage containers

For custom size production requests, please contact us.

Application Examples